Mechanics of Materials forms the backbone of engineering design. It explains how materials behave under different forces and loads. Let’s dive into the fundamentals of stress and strain, two essential concepts every engineer should master. 📘

Table of Contents 📚

- What is Stress? 🧠

- Understanding Strain 🧵

- Stress-Strain Curve Explained 📈

- Types of Stress and Strain 🛠️

- Applications in Real Life 🌍

- FAQs ❓

What is Stress? 🧠

Stress measures how much force a material experiences over a given area. Think of it as the “pressure” exerted on an object.

Formula 🧮:

Stress=Force (F)Area (A)\text{Stress} = \frac{\text{Force (F)}}{\text{Area (A)}}Stress=Area (A)Force (F)

- Unit: Pascals (Pa) or N/m²

- Types:

- Tensile Stress ➡️ Stretches the material

- Compressive Stress ⬅️ Pushes the material

- Shear Stress ↔️ Slides layers against each other

| Stress Type | Symbol | Real-Life Example |

|---|---|---|

| Tensile Stress | σ | Stretching a rubber band 🪢 |

| Compressive Stress | σ | Squeezing a soda can 🥤 |

| Shear Stress | τ | Cutting paper with scissors ✂️ |

🔗 Related Topic: Read more about force analysis here.

Understanding Strain 🧵

While stress measures the cause, strain measures the effect. It’s the material’s deformation relative to its original size.

Formula 🧮:

Strain=Change in Length (ΔL)Original Length (L₀)\text{Strain} = \frac{\text{Change in Length (ΔL)}}{\text{Original Length (L₀)}}Strain=Original Length (L₀)Change in Length (ΔL)

- Unit: Dimensionless (ratio)

- Types:

- Tensile Strain ➡️ Stretching

- Compressive Strain ⬅️ Shortening

- Shear Strain ↔️ Distortion

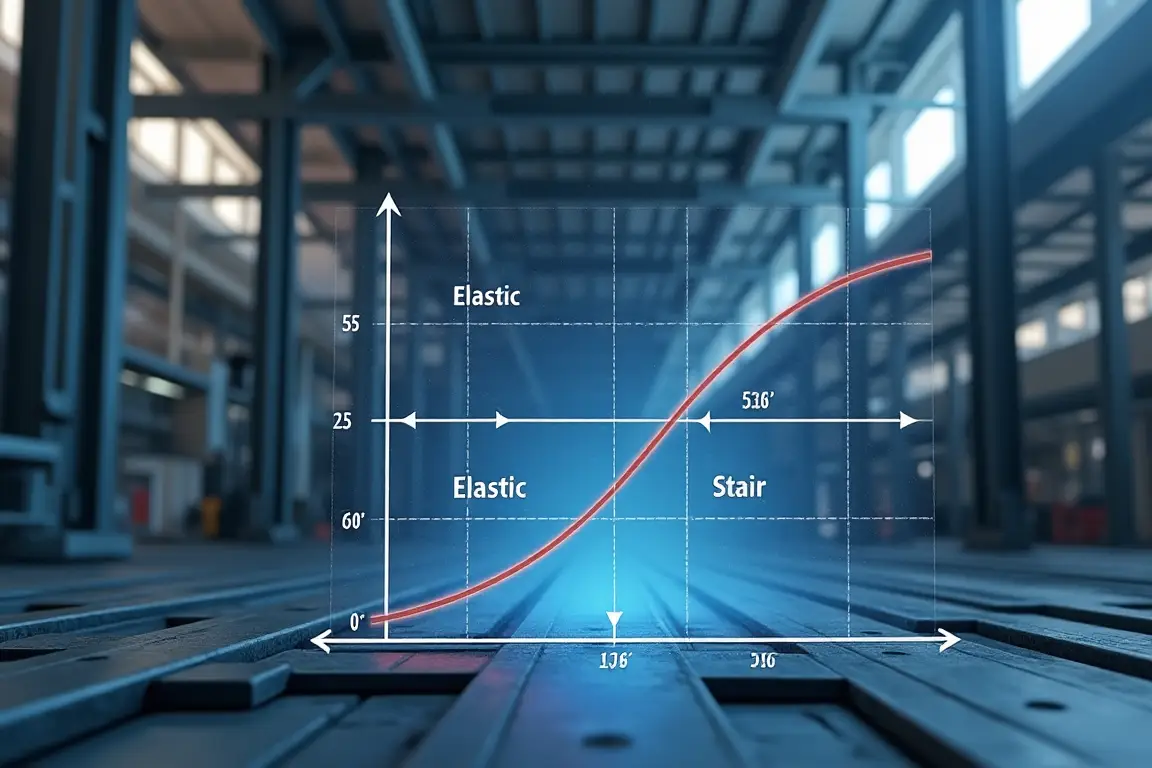

Stress-Strain Curve Explained 📈

The stress-strain curve reveals a material’s behavior under stress. Engineers rely on it to predict performance and failure.

Key Points on the Curve:

- Elastic Region ⚡: Material returns to its original shape.

- Yield Point ⚠️: Permanent deformation starts.

- Ultimate Strength 💪: Maximum stress the material can handle.

- Fracture Point 💔: Material breaks.

| Region | Behavior | Example |

|---|---|---|

| Elastic Region | Temporary deformation | Stretching a spring 🌀 |

| Plastic Region | Permanent deformation | Bending a paper clip 📎 |

| Fracture Point | Material fails | Snapping a pencil ✏️ |

Visualization:

(Include a visual chart of the stress-strain curve for clarity.)

Types of Stress and Strain 🛠️

| Stress/Strain Type | Definition | Application |

|---|---|---|

| Tensile Stress | Stretching force | Bridges and cables 🌉 |

| Compressive Stress | Squeezing force | Columns in buildings 🏛️ |

| Shear Stress | Sliding force | Gears and joints ⚙️ |

| Tensile Strain | Elongation | Wires and ropes 🧵 |

| Compressive Strain | Shortening | Concrete under pressure 🏗️ |

| Shear Strain | Distortion | Riveted or bolted joints 🔩 |

Applications in Real Life 🌍

Mechanics of Materials plays a vital role in:

- Bridge Design 🌉: To withstand tensile and compressive stresses.

- Aerospace Engineering ✈️: Lightweight materials resisting extreme forces.

- Construction 🏗️: Analyzing concrete and steel for buildings.

- Automobile Industry 🚗: Materials absorbing impact during collisions.

🔗 Further Reading: Explore material selection in engineering.

FAQs ❓

1. Why is stress important in engineering?

Stress analysis helps prevent structural failure, ensuring safety and efficiency.

2. What happens if strain exceeds limits?

Excessive strain causes materials to fail, often catastrophically.

3. How do I calculate safety factors?

Safety Factor = Ultimate Strength / Working Stress.

4. What is the role of Young’s Modulus?

Young’s Modulus determines material stiffness and elasticity.

🔗 Learn More: Dive deeper into material properties.

Final Thoughts 🛠️

Understanding stress and strain is fundamental for engineers. It ensures safe, efficient, and innovative designs. By mastering these concepts, we can build stronger structures, develop lighter vehicles, and create smarter materials. 🌟

🔗 Internal Links:

🔗 External Resources:

- Learn from ASME resources on Mechanics of Materials.

- Explore online material databases.